You are here

Journal Club Theme of May 2015: Mechanics of nanobionic materials

Case study: Cyberwood

In a paper published recently in the Proceedings of the National Academy of Science [1], we introduced a new synthetic material that consists of carbon nanotubes embedded into a matrix of plant cells from the tobacco plant. The new material has mechanical and structural properties resembling wood; we call it cyberwood. Unlike wood, however, it is exquisitely sensitive to temperature changes: it is electrically conducting, and its conductivity changes with temperature, with a sensitivity that is two orders of magnitude greater than that of other existing materials. Cyberwood achieves this high sensitivity by preserving plant cells’ natural ability to sense temperature variations even after their death. Combining biological cells with nanoparticles, cyberwood is a “nanobionic material”, a class of materials that aims to preserve, enhance, and exploit properties of living systems for engineering purposes.

The creation of materials that bridge the living and inanimate world has been a longstanding challenge for materials scientists, chemists, mechanicians and engineers. Most attempts have focused on reverse engineering biological structures, on biomimicking, and on bioinspiration. Wood, in particular, has inspired the design of new materials, thanks to its versatility, structural complexity and excellent resistance to failure (see, for example the recent Nature News and Views article [2]). In most cases, however, creating synthetic materials that reproduce or surpass the performance of natural materials has been elusive. Biological materials often form complex, hierarchical and composite structures, which respond optimally for a given purpose under specific environmental conditions [3]. Nanobionic engineering, and most recently “plant-nanobionics” [4], is an emerging field that seeks to develop systems with enhanced properties. But reaching the level of nano- to macro-scale control necessary to achieve the performance of complex natural systems has been a challenge for existing fabrication methods.

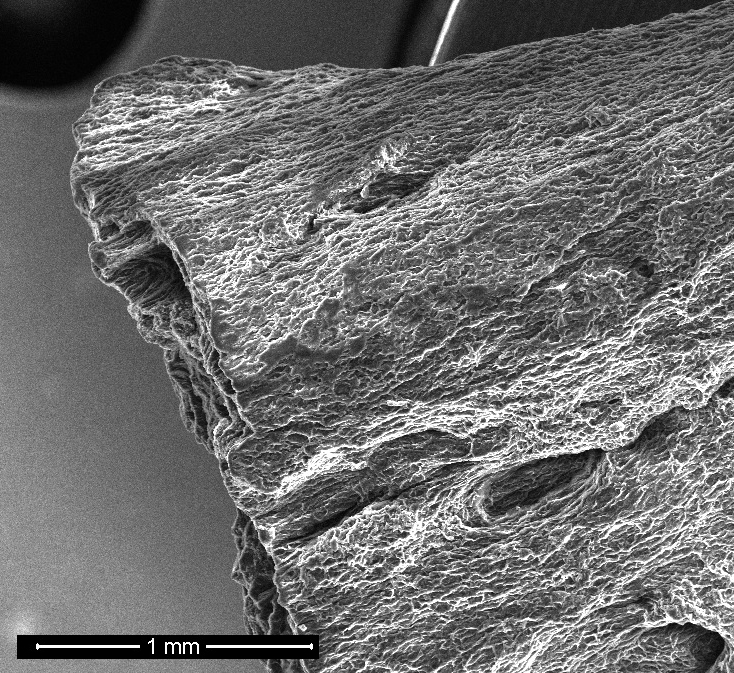

To synthesize cyberwood, we combined several conventional nano-synthesis approaches. We let biology drive the fabrication of the final materials, by culturing undifferentiated plant cells in a growth medium that contained carbon nanotubes. The cells self-assembled to form a soft gel, and they carried along the carbon nanotubes by partially anchoring them to their cell wall. When we stopped the process and let the soft gel dry, a material formed that has a complex, hierarchical structure, similar to wood. Cyberwood can be produced at very low cost and in large quantities, it can be worked, but also molded into arbitrary shapes. Because of its exquisite temperature sensitivity, it may find applications in thermal sensors, for example, for thermal cameras, or in distance sensors for consumer products and security systems. Its excellent structural and mechanical properties suggest applications in smart building technology.

Figure: Scanning electron micrograph (SEM) of cyberwood. The image is adapted from [1], Copyright (2015) National Academy of Sciences, USA.

The future

One avenue for creating new, multifunctional materials that match or even outperform natural systems may be to “let nature fabricate for us.” Molecular self-assembly is routinely used in chemistry; see the review of the “Mechanics of biological and bio-inspired supramolecular assemblies” on iMechanica. Fabrication driven by simple organisms (e.g., viruses) has shown promise in disparate fields, like energy and medicine (see e.g., [5, 6]).

Fabrication of hierarchical materials driven by more complex biological cells and organisms is a new concept. It allows us not only to be “inspired” by hierarchical natural materials, but also to directly capitalize on nature’s own ability to synthesize such complex structures. Plants are a natural starting point for this: they are easy to culture, form complex hierarchical systems and present many properties useful for engineering purposes. Hundreds of thousands of plant species offer an enormous variety of material properties. Exploiting these natural properties opens rich opportunities to design, fabricate and test new materials.

The role of mechanics

Mechanics has naturally played an important role in the creation of bio-materials, and this is reflected also in several earlier blog-entries on iMechanica. See, for example, the entries by Michelle L. Oyen on the “Role of mechanics in biomimetics”, by Sinan Keten on the “Mechanics of Protein Structures and Materials - Silks, Amyloids and Muscle Fibers”, by Howon Lee on the “Three Dimensional Biologically Inspired Microvascular Systems”, by Ashkan Vaziri on the “Mechanics of Biological and Biomimetic Cellular Structures” and, in the most recent blog entry by Yuhang Hu, from last month.

Creating nano-bionic materials that combine living cells with synthetic nano-structures is an emerging area of research. It offers numerous opportunities to create materials with properties so far only found in nature, or to obtain properties not yet existing at all.

From a scientific point of view, understanding the fundamental principles governing the mechanics of nano-bionic materials is difficult, because of the complexity of biological systems. Cells are intricate units in which many variables can contribute to a specific response. Isolating the most important ones requires numerous, well thought experiments.

From an engineering point of view, one of the biggest difficulties in this research area arises from the absence of predictive theoretical models to guide the design of nano-bionic materials. Much is dependent on the scientists’ intuition and creativity, developed and guided by systematic experimentation. The numerical and experimental tools of mechanics are a great resource to jump-start the field of mechanical nano-bionics. Because the natural components of living cells are primarily soft bio-polymers, much can be learnt from the rheology and mechanics of soft materials and gels (for example, a great resource is the blog on “Stretchable ionics”) and from the combination of soft gels with rigid fibers and particles (see, for example, the recent Extreme Mechanics Letters paper on “Fiber-reinforced tough hydrogels” [7]).

We are excited about the prospects of nano-bionic materials. In our ongoing work, we are continuing to explore the mechanics of cyberwood. We are also extending the cell-driven fabrication approaches to different plant cells and organisms, pairing them with different synthetic nanostructures. We experiment with the finished products, in our quest to engineer the next materials and devices that in one way or another may benefit society at large.

Acknowledgements

The work on cyberwood and other plant nanobionic materials in our lab has been spearheaded by Dr. Raffaele Di Giacomo. More recently, we acknowledge the work of Luca Bonanomi (PhD student), Andre’ Fischer (former Master student), and Vincenzo Costanza (current Master student). We collaborate with the group of Prof. Bruno Maresca from the University of Salerno, Italy.

References

- Di Giacomo, R; Daraio, C.; Maresca, B. "Plant nanobionic materials with a giant temperature response mediated by pectin-Ca2+", Proceedings of the National Academy of Sciences, 112, 15, 4541–4545 (2015).

- Ball, P. “Material witness: Watching wood dry” Nature Materials 13, 922 (2014).

- Sanchez, C.; Arribart H.; Giraud Guille, M. M. “Biomimetism and bioinspiration as tools for the design of innovative materials and systems”, Nature Materials, 4, 277 - 288 (2005).

- Giraldo, J.P., et al. “Plant nanobionics approach to augment photosynthesis and biochemical sensing”, Nature Materials, 13, 400–408 (2014).

- Lee, S.-W.; Mao, C.; Flynn, C.E.; Belcher, A.M. “Ordering of Quantum Dots Using Genetically Engineered Viruses” Science, 296, 5569, 892-895 (2002)

- Nam, K.T., et al., “Virus-Enabled Synthesis and Assembly of Nanowires for Lithium Ion Battery Electrodes” Science, 312, 5775, 885-888 (2006).

- Illeperuma, W.R.K.; Sun, J.-Y.; Suo, Z.; Vlassak, J.J. “Fiber-reinforced tough hydrogels” Extreme Mechanics Letters, 1, 90-96 (2014).

| Attachment | Size |

|---|---|

| 511.67 KB |

- cdaraio's blog

- Log in or register to post comments

- 13404 reads

Comments

Intriguing idea

Hi Chiara,

It is a very innovative idea of combining plan cells and carbon nanotube to form cyberwood, which possesses superb stimuli sensitivity. Congratulations for the excellent work. I enjoyed reading your paper. Several questions in my mind which may turn out to be very superficial:

1. what is the weight percentage of carbon nanotube in cyberwood? I remember that a few percentage carbon nanotube in a polymer matrix can percolate to form a network. Once the carbon nanotube network forms, electrical conductivity of the mateiral may be only determined by the carbon nanotube network (I assume carbon nanotube have a much higher electrical conductivity than plant cell).

2. Do you expect any electrochemical reactions between carbon nanotube and calcium ions? How does charge pass through ions to carbon nanotube?

3. Do you expect a pure pectin-gel matrix carbon nanotube composite have similar or even better performance than cyberwood? Of course, cyberwood may be more scalable and easier to make.

Best

shengqiang

Re: Intriguing idea

Dear Shengqiang,

Thank you for your comments. The questions you asked get to the core of the topic:

1. We do not know the exact weight percentage of carbon nanotubes (CNTs) in cyberwood. However, the amount of CNTs in cyberwood is very small - we estimate it to be in the order of few 10s -100s nanograms of CNTs per gram of cyberwood. Too many CNTs would prevent the temperature sensitivity to be measurable, too few would not allow to achieve sufficient structural stability and electrical interconnectivity between the cells.

2. We do not expect electrochemical reactions between the CNTs and the Ca2+ ions. The mechanism for charge passage is related to the creation of an electric potential with increasing release of ions from the pectin, as a consequence of the temperature increase. The charge transfer mechanism is the same as the one that allows "Ionic cables" to transmit music signals, or power LEDs (see also the iMechanica journal club entry on "stretchable ionics").

3. We are now studying the properties of a pecting-gel matrix. Indeed, we also believe it should have a similar temperature responsivity to cyberwood.

Hi Chiara, many thanks for

Hi Chiara, many thanks for your clarification!

is it safe

Hi Chiara,

That was very interesting! I wonder, however, whether the use of hardly destroyable nanotubes is safe for our health?

Best,

Kosta

Re: is it safe

Dear Kosta,

Your point is well taken. Carbon nanotubes (CNTs), even if embedded in a matrix, are a safety concern. We are actively looking into ways to avoid having to rely on CNTs. We are also expanding our initial work on nanobionic materials to other plant cells/nanoparticles combinations. There is a lot of work to be done, and many questions that remain unanswered. We hope the broader mechanics community will get interested in them!

Best regards,

Chiara